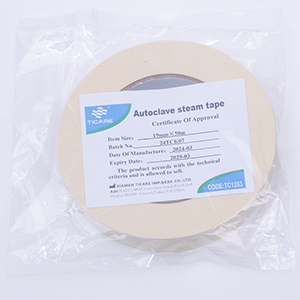

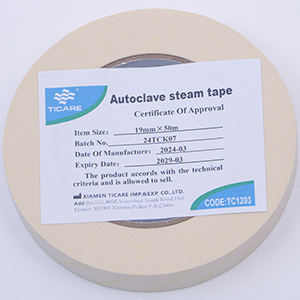

Autoclave tape indicator is a specialized tape used in sterilization processes to confirm whether an item has been exposed to the correct conditions for sterilization, specifically in an autoclave. Autoclaves use high pressure and temperature (typically around 121–134°C or 250–273°F) to sterilize medical instruments, laboratory equipment, and other items that must be free of pathogens.

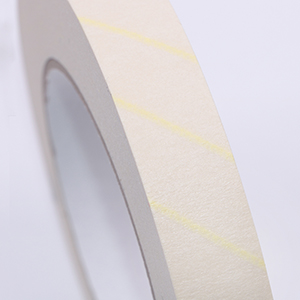

Autoclave tape contains chemical indicators that change color when exposed to the specific temperature and pressure conditions inside an autoclave. The color change is typically from light to dark (commonly from beige or tan to black or brown), indicating that the item has undergone the required sterilization process.

Indication of Exposure to Sterilization Conditions: Autoclave tape is primarily used to visually verify that the items have been exposed to the proper sterilizing conditions.

Not a Sterility Assurance: It's important to note that autoclave tape does not guarantee sterility. It only confirms that the item has been exposed to the correct temperature and pressure. To ensure sterility, other processes, such as biological or chemical indicators, should be used in conjunction with the tape.

Identification: It is also useful for labeling and identifying items or packages that have been autoclaved, ensuring that personnel know which items have undergone sterilization.

While autoclave tape is helpful, it is not a foolproof method of ensuring sterility. It does not check the duration of exposure or whether steam penetration was adequate throughout the load. For more accurate monitoring of sterilization, professionals often use biological indicators (e.g., spore tests) and chemical indicator strips that provide more comprehensive feedback on sterilization efficacy.

In summary, autoclave tape indicators are essential tools for confirming that sterilization conditions have been met, but they should be part of a broader sterilization validation protocol.